GFRP rebar is changing the construction industry with its innovative properties and significant business advantages. Unlike conventional steel reinforcement, GFRP offers exceptional corrosion resistance, high tensile strength, and lightweight characteristics, making it an ideal choice for an impressive range of applications.

Starting an FRP rebar manufacturing business is beneficial due to the growing demand for the material. Hence, choosing a good rebar manufacturing equipment supplier ensures consistent product quality, operational efficiency, and advanced technology.

GFRP Rebar: What Is It?

GFRP, an acronym that stands for Glass Fiber Reinforced Polymer, rebar is a composite material used for reinforcement of concrete structures. Made by combining glass fibers with a polymer resin, GFRP rebar provides significant advantages in terms of durability, weight, and resistance to environmental factors such as chemicals and moisture.

The FRP rebar production lines are crucial in manufacturing high-quality rebar, as they ensure consistent fiber alignment, precise resin impregnation, and optimal curing processes. This precision in manufacturing is essential to achieve the desired mechanical properties and longevity, making GFRP rebar an increasingly popular choice in construction applications where durability and performance are critical.

Why Choose a Fiberglass Rebar?

Reduced maintenance and replacement costs, simplified transportation and handling, lower labor costs, and faster construction times are among the key business benefits of GFRP compared to steel rebar.

The primary advantages of reinforced glass fiber include:

- Resistance to corrosion makes FRP ideal for use in environments exposed to moisture, chemicals, and salts, such as marine and coastal structures.

- Lightweight. GFRP rebar is much lighter than steel rebar, which reduces transportation and handling costs and makes it easier to install.

- The non-magnetic properties of GFRP make it advantageous in applications where magnetic interference should be minimized, such as in certain military and research facilities.

- Non-conductive properties make GFRP suitable for use in structures where electromagnetic neutrality is required, such as in MRI rooms or around sensitive electronic equipment.

- Thermal resistance. GFRP rebar does not expand or contract with temperature changes as much as steel, reducing the risk of cracking in concrete structures due to thermal stress.

- High tensile strength. Despite its lightweight nature, GFRP is renowned for its high strength-to-weight ratio.

- Longer lifespan due to FRP resistance to environmental degradation, which reduces maintenance and replacement costs over time.

- Sustainability. GFRP rebar production has a lower environmental impact than steel, with less energy consumption and fewer greenhouse gas emissions.

The diverse applications highlight GFRP rebar’s versatility and effectiveness in enhancing the longevity and performance of structures across various sectors, including the construction sector, mining, agriculture, healthcare, military, transportation, utilities, etc.

Collaborate with Experts: Composite-Tech

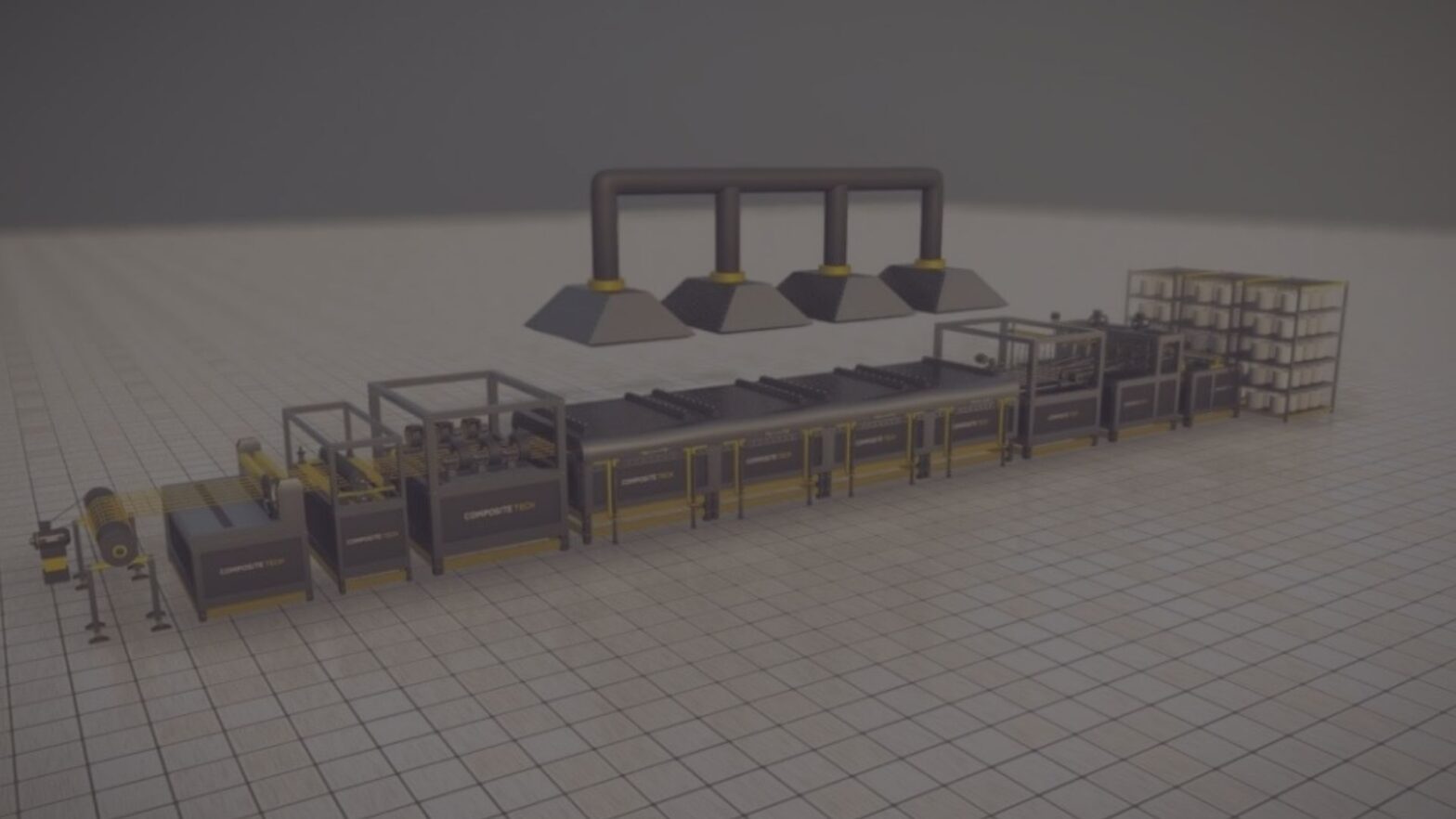

Composite-Tech is renowned worldwide: the company has a strong reputation in the industry. It is trusted by clients globally for its reliable and high-quality production lines. The company has developed fiberglass and basalt rebar manufacturing lines, a technology the team has refined into a turn-key solution. The advanced composite production technology is a collaborative effort with research institutions and regulators from the USA, Canada, Japan, Russia, Italy, and the Netherlands.

Today, Composite-Tech supplies fiberglass/basalt rebar, mesh, and bent element production lines globally, launching a new era of construction that is more secure and resistant to the effects of time and weather.

The range of Composite-Tech production lines includes:

- GFRP rebar production lines

- GFRP Mesh production lines

- GFRP bent elements production line

- FRP pipe production line

- FRP tank production line

- FRP composite silo production line

- FRP profile production line

Factors to Consider While Choosing a GFRP Production Lines Manufacturer

By considering the below-listed aspects and understanding the importance of choosing a reliable GFRP rebar production line manufacturer, enterprises can ensure they receive high-quality products that help to achieve their business goals.

- Reputation and experience. Research the manufacturer’s history in the industry. Look for companies with a solid track record and extensive experience.

- Quality standards and certifications. Verify that the manufacturer adheres to international quality standards and check for specific certifications related to GFRP rebar production.

- Technology and innovation. Ensure the manufacturer uses state-of-the-art technology and innovative production processes.

- Customer reviews and references. Read reviews and testimonials from other customers.

- Production capacity and scalability. Assess the manufacturer’s production capacity to ensure they can meet your demand.

- Technical support and service. Evaluate the level of technical support and after-sales service provided. Ensure they offer comprehensive training, maintenance, and troubleshooting assistance.

- Cost and value. Compare costs and consider the overall value, including product quality, reliability, and service.

5 Advantages of Partnership with Composite-Tech

Composite-Tech is considered one of the best GFRP rebar machine manufacturers for the following reasons:

- Composite-Tech employs state-of-the-art technology in their production lines, ensuring high precision and efficiency in the manufacturing process.

- Extensive experience & technical expertise. With years of experience in the industry, Composite-Tech has developed a deep understanding of GFRP rebar production and refined processes to deliver superior products.

- Quality assurance. The company applies stringent quality control measures and international standards to ensure that every product meets high-quality benchmarks and performance requirements.

- Customer service. The company has a strong reputation for excellent customer service, providing comprehensive support, training, and after-sales service to ensure customer satisfaction.

- Sustainability and environmental compliance. Composite-Tech is committed to sustainable practices and complies with environmental regulations, ensuring their production processes are eco-friendly.

These factors collectively make Composite-Tech a leading choice for potential GFRP rebar manufacturers, ensuring high-quality products, reliable service, and continuous innovation.

GFRP rebar production is a highly profitable investment with a fast payback period. By investing in GFRP rebar production lines, manufacturers can capitalize on this growing market trend while contributing to environmental sustainability.

Additionally, advancements in production technology and the availability of turnkey solutions from leading manufacturers like Composite-Tech ensure that setting up and operating GFRP rebar production lines is more accessible and efficient than ever.

With these advantages, investing in GFRP rebar production lines not only promises significant returns but also positions businesses at the forefront of modern construction innovation.