How to Make 3D Models for Printing: Guide for Beginners

3D printing has unveiled a universe of boundless opportunities, enabling the fabrication of detailed and tailor-made items. A wealth of knowledge exists for those wondering how to make a 3D model for printing. As exhilarating as seeing a design come to life in 3D form is, mastering how to design 3D prints and understanding the design phase is just as paramount. If you’re new to this world and aiming to learn how to make 3D models for printing, this guide will demystify the process, ensuring you’re equipped to turn your imaginative designs into tangible models.

Before you delve into how to create a 3D model for printing, begin with clarity. Whether you’re recreating a real-world object or birthing a new concept, sketches can serve as blueprints. This aids in visualizing dimensions and spatial relationships when making 3D printer models. Exploring platforms like Thingiverse can acquaint you with design trends and common pitfalls. Analyzing top-rated designs lets you discern what makes a model printable and popular. Studying top-rated techniques lets you determine what features contribute to a model’s popularity. For instance, cost-effective large scale 3D printer can be a significant factor in their appeal. Also, they act as a roadmap, particularly when you’re trying to grasp how to make 3D printer models and help visualize the spatial dimensions.

The final purpose of your design has significant implications for its creation process. Durability, weight, and material compatibility become paramount when creating a functional part. For decorative pieces, aesthetics might take the forefront. But aesthetics will undoubtedly take precedence if you’re exploring how to design 3D print models for ornamental purposes.

Choose the Right 3D Modeling Software

Your choice of software should reflect your comfort level and the intricacy of your design. TinkerCAD, with its user-friendly interface, is a haven for those wondering how to make your own 3D print design without a steep learning curve. Conversely, Blender and AutoCAD, packed with advanced features, cater to intricate designs and those already versed in how to design 3D prints.

Not all software options are created equal. Prioritize those that export in STL or OBJ formats, which are universally accepted by most 3D printers. Additionally, online forums associated with particular software can provide user-generated tips, tutorials, and solutions. Invest time in tutorials. Software-specific tutorials offer insights into hidden tools and shortcuts, enabling you to harness the software’s full potential. As you explore how to make designs for 3D printer, investing time in software-centric tutorials can unveil lesser-known tools and shortcuts, allowing you to optimize the software’s capabilities fully.

Begin Modeling Your Design

While it might seem daunting at first, start with primary shapes. Consider these as building blocks when considering how to make 3D models for printing. This foundational knowledge sets the stage for complex designs. 3D printing constructs objects layer by layer. By segmenting your design mentally into these layers, you ensure smoother transitions, especially in formats with intricate curves or angles. 3D printing can capture remarkable detail, so always ensure your model has the necessary intricacies. These minor elements can elevate the final print, whether it’s a texture, a logo, or a minute design change.

Refine and Optimize Your Model for 3D Printing

Software often comes with diagnostic tools that can detect potential print errors. Agencies can identify problematic overhangs, thin walls, or areas that might not bond correctly during printing. While you may have a grand design, ensure it fits within your printer’s build volume. However, you can always segment larger structures and assemble them post-print when studying how to create 3D models for printing. An optimal wall thickness ensures durability and material efficiency. While a thin wall might lead to print failures or fragile parts, an excessively thick one could waste material and time.

Export Your Model in the Appropriate Format

For those passionate about 3D printing and keen on learning how to make 3D printer models, understanding the intricacies of design formats is pivotal. Using universally accepted formats like STL or OBJ is not just a recommendation; it’s a necessity, ensuring that your design effortlessly transitions from your software to the printer. As you embark on the journey of how to make your own 3D print design, you’ll find tools such as Cura or PrusaSlicer to be indispensable allies. These tools offer previews of how the final print will appear and empower you to tweak and refine your design, catching any potential pitfalls before they materialize. Moreover, the art of 3D design is also about iteration and evolution. Using cloud storage, you can effectively document and archive different versions of your work, ensuring that no innovative idea goes unnoticed.

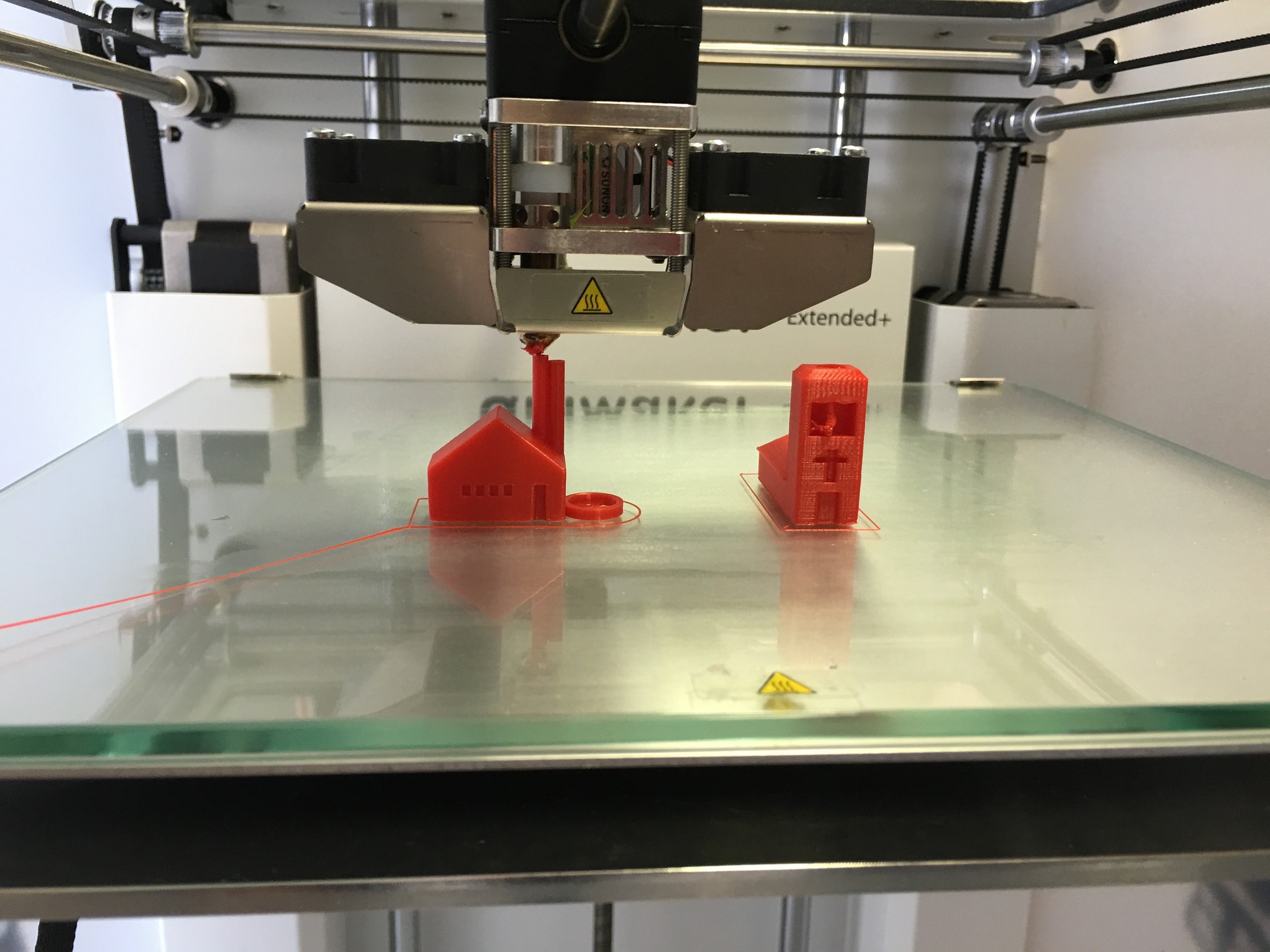

Prepare Your Printer and Start the Print

Calibration is a cornerstone when diving into 3D printing and understanding how to design 3D prints. Starting with a well-leveled print bed ensures that your 3D print models have a solid foundation, preventing potential issues down the line. The intricacies of choosing the optimal nozzle temperature and the right filament type can’t be overlooked, as these factors are pivotal for those exploring how to make designs for 3D printers. While the process may seem straightforward, keeping a vigilant eye is essential, especially when printing initial layers. These layers can offer early indicators of the final product’s quality. So, for those passionate about mastering the craft of 3D printing, it’s not just about speed; it’s about ensuring precision, understanding, and knowledge of how to design 3D printed models with finesse.

An Afterword

The journey from a conceptual design to a physical print combines creativity, technical knowledge, and patience. By following each step precisely and continuously improving your approach, you can create exceptional, one-of-a-kind 3D printed models. You became a part of art and science when discovering how to make 3D printer models. While the technical facets ensure a successful print, the artistic elements breathe life into the design. As you embark on this journey, cherish every learning curve and be open to feedback. By dedicating yourself with passion, your 3D creations will soon mesmerize and motivate others.