If you’re in the market for a robotic polishing system, there’s much to think about before making the investment.

From recognizing your specific needs and comparing different models, to planning installation and considering ongoing maintenance requirements, each step counts. Ensuring safety measures while implementing a cost-benefit analysis is equally important.

With that in mind, here’s a comprehensive overview of key considerations that will help ensure a successful purchasing journey.

Recognizing Your Specific Needs for a Robotic Polishing System

Before getting started with robotic polishing, it’s crucial to identify what your specific needs are. Think about the following factors:

- Material Types: The type of material you need polished can greatly influence which robotic polishing systems will work best for you. For instance, steel requires different handling than aluminum or plastic.

- Product Quantity and Size: Are you producing large components in small quantities? Or smaller parts on a mass scale? These aspects impact on the size, capacity and speed of the robot polisher needed.

- Available Workspace: You should consider how much space is available in your facility for installing this new hardware. It’s important the machine fits adequately without obstructing any existing operations.

Nailing down these particulars first will help narrow down options that suit your production environment best.

The Essentials of Installation Process

A successful installation process blends detailed planning with expert execution. Here are some critical factors you should consider:

- Location: Consider the space and location within your workplace, ensuring there’s ample room for movement during polishing operations.

- Power Supply: Confirm that your facility has reliable power sources able to sustain the system’s load without causing interruptions in other areas of operation.

- Connectivity Requirements: Many robotic systems rely on network connectivity for maximum functionality. Having a robust network infrastructure is crucial.

- Training: Does the supplier provide training to operators following installation? Understanding how to run the machine safely and efficiently helps avoid unexpected breakdowns or accidents. This may be required as part of your broader on-site safety training efforts.

Arranging these details ahead makes launching your new automated equipment a smoother process and ensures optimal productivity right from the start.

Factoring in the Ongoing Maintenance Requirements

Maintenance and system upkeep are central to ensuring that your robotic polishing systems remain efficient over time. Keep these aspects in mind:

- Routine Care: Regular cleaning and component check-ups aid in identifying any latent issues before they become full-blown problems.

- Software Updates: Automated equipment frequently needs software updates for optimal performance. Check how often these occur, their complexity, and whether you need an expert’s assistance for them.

- Spare Parts Availability: As with all machines, parts will inevitably break down or wear out. You should confirm accessibility and cost of spare parts from your supplier.

- Technical Support: A reliable customer support service from your manufacturer is invaluable. They can offer advice when things go wrong and help troubleshoot issues promptly.

Securing each of these factors ensures your robotic polisher remains operational longer while minimizing downtime.

Considerations for Safety Measures with Automation Equipment

As much as robotic polishers can increase efficiency, they also introduce unique safety concerns. Below are a few considerations:

- Operator Training: As mentioned, ensure operators receive adequate training not only on how to use the systems but also on potential risks and appropriate responses.

- Machine Guarding: Consider protective barriers such as fences or light curtains around your robotic polisher to prevent personnel from straying into areas of operation during cycles.

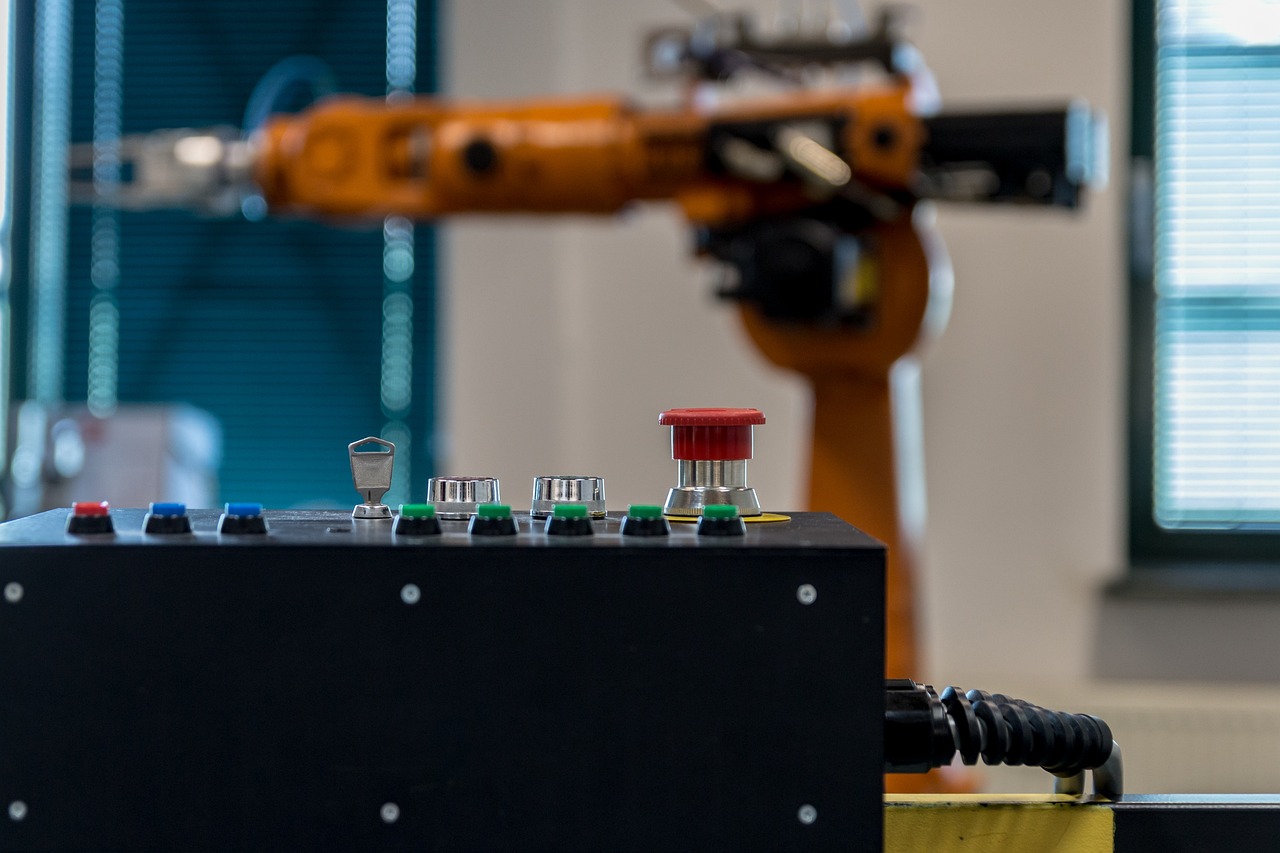

- Emergency Stops: Robotic equipment should have easily accessible emergency stop buttons. This precaution allows immediate halting of operations in case something goes awry.

- Regular Inspection: Preemptive identification of any malfunctions through frequent inspections reduces chances of sudden accidents due to failure in part or system malfunction.

Addressing these safety measures promotes a secure working environment while maximizing productivity.

Wrapping Up

Now that you’re equipped with all this knowledge, you are in a strong position to start your search for a robotic polishing system that works for your business. So get out there and don’t delay any longer!