Dutch startup Monumental recently emerged from stealth mode and is attracting attention for its robotic bricklaying system. What features capture people’s interest the most, and why should you consider implementing robots into the workflow?

A Thoughtful, Safe Approach

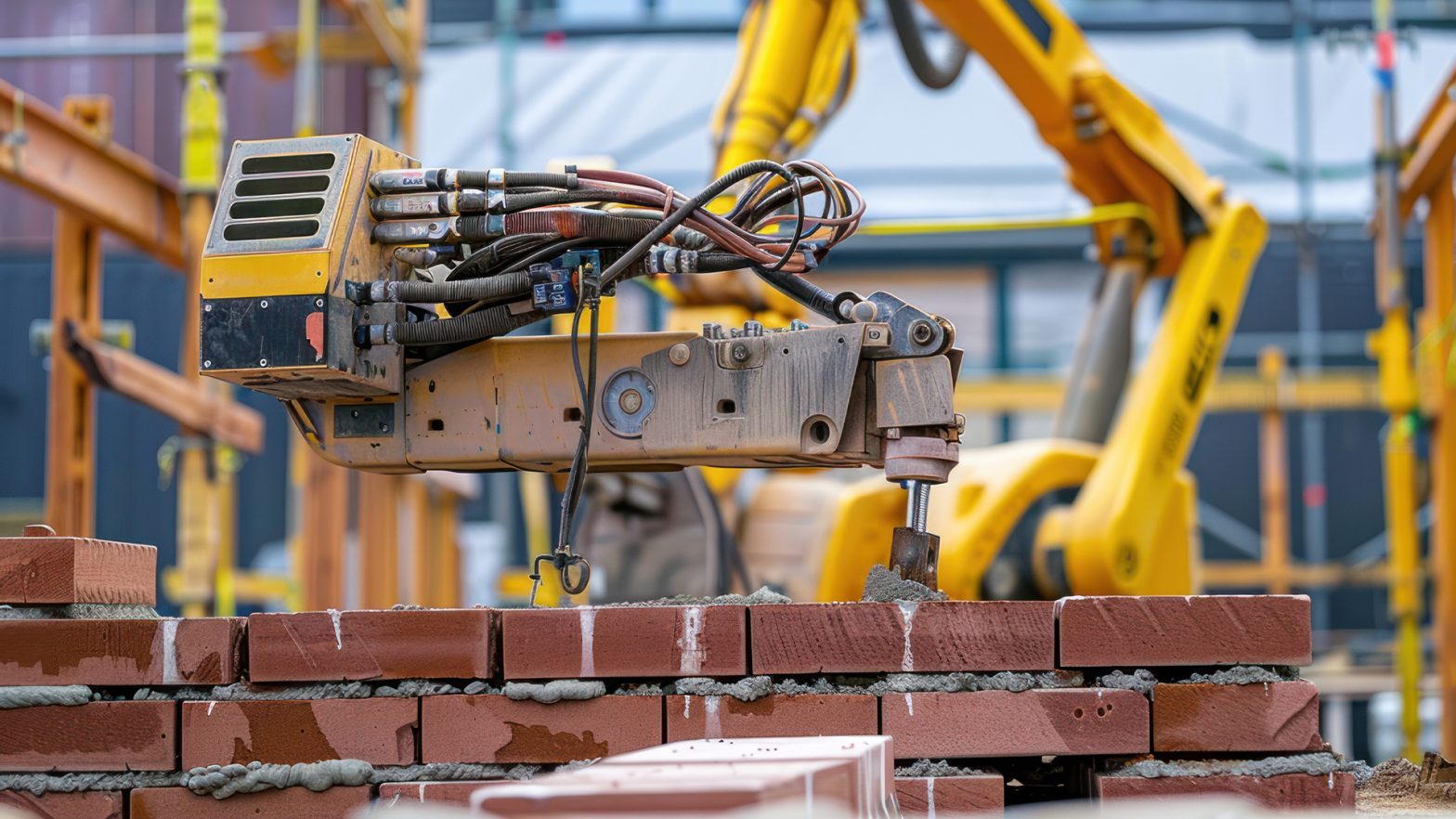

Other bricklaying robots arrived before Monumental’s technology. However, the founders capitalised on those earlier options by improving their concepts when possible. The first way that becomes evident is through its approach, which uses several robots for different purposes. Earlier solutions sometimes involved all-in-one machines that were much larger and sometimes too massive for particular projects.

The brand’s system relies on three robots. The first one picks up bricks and brings them to another machine that will lay them correctly. Another takes a similar approach when giving the mortar to the last machine in the trio. The bricklaying robot has a pair of tower cranes, allowing it to install the blocks at the ground level, up to the top part of a building’s lowest floor.

When it is time to move to the higher storeys, the third robot moves into a scissor lift to reach them. All the brick-placement and mortar applications happen autonomously. The robotic system works alongside humans, who handle steps such as smoothing the mortar or installing the wall ties to anchor the bricks.

Construction work requires keeping people safe with thorough risk assessments, safety plans and reduction measures. These robots could promote safety by eliminating or reducing steps that cause fatigue and potential injuries.

The advanced machines also use artificial intelligence and can scale to meet needs associated with larger projects. City planners must identify creative and effective coping strategies as many areas struggle with housing shortages. Robots could contribute to such progress.

Productivity Potential

The construction industry accounts for approximately 13% of the world’s gross domestic product. However, estimates also suggest better productivity could unlock more than $1.5 trillion in overall value.

The coverage of competing robots often emphasises how much quicker those machines are than humans. For example, one option worked up to 20 times faster than people when laying a home’s brick framework. That alternative has a telescoping boom arm to reach a structure’s upper storeys.

However, Monumental’s system works about as efficiently as people do. Construction site managers could boost productivity by deploying more than one at each location to increase the overall output. That could be a feasible way to deal with bricklayer shortages.

The technology needs only one person to oversee the machines as they work. The associated service charges for that human oversight cost about the same as a human bricklayer. However, robots do not get tired or distracted. Those characteristics could make them give more consistent results than people.

Additionally, bricklayer shortages mean leaders often must spend more and risk their projects going outside stated timelines. They could prevent those outcomes by investing in robots that are always ready to work. Although this approach does not remove the need to hire humans, projects can continue progressing with fewer people per site.

The service costs associated with Monumental’s system include hiring a construction robot operator. Recent postings for this position on the business’s site suggest applicants do not need engineering degrees or prior construction site experience. Still, an analytical, problem-solving approach will go far in these roles.

That is a strong example of the changing construction sector and how the future likely will not require so much manual labour. Staying abreast of these developments will help decision-makers thrive while experiencing them.

Accessibility

Construction site leaders and other decision-makers will be more likely to invest in new technology if it fits easily into their budgets. Monumental’s executives stayed conscious of that reality by offering solutions at one-tenth the cost of competing products. However, the enterprise charges customers by the number of bricks laid, replicating a popular European model.

Since Monumental charges a per-brick rate, it is easier for site leaders to calculate the overall costs and compare them to their current processes. The expenses should also be more stable because they do not have to work with multiple bricklayers who may charge various rates.

Another perk that makes Monumental’s robots particularly appealing to modern construction leaders is they can lay the bricks in numerous patterns. That versatility makes it easier to justify embracing automation.

Many people do not like the cookie-cutter appearance common to some bricklaying robots that can handle one or two arranging styles. Monumental’s team overcame that challenge by making their robots able to handle a wider range of current and potential needs.

The accessibility aspect also applies to the smaller footprint offered by the brand’s technology. The system’s more compact dimensions allow it to fit through some doorways.

A Robotic System Worth Considering

These are some of the features that have helped Momentum gain traction in Europe and gain notice elsewhere. The company’s technology has come at an ideal time, as many site leaders grapple with increasing workloads while labour shortages persist. Using robots to supplement humans’ tasks could keep projects on schedule and under budget, making it easier for firms to secure more work and stay profitable.